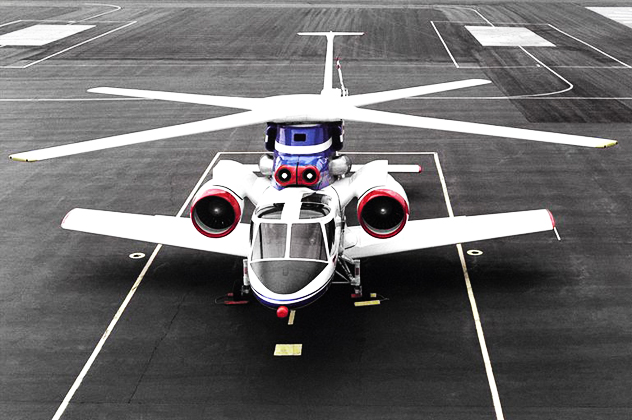

10Sikorsky X-Wing

Famous helicopter manufacturer Sikorsky came the closest to giving the world a real version of the X-wing fighter from Star Wars. In the mid-1970s, Sikorsky began playing with experimental helicopter designs, combining new power plants with leading aerodynamics. The key airframe for these experiments was the S-72 Rotor Systems Research Aircraft. Originally, the S-72 just tested out the possibilities of a mixed airplane/helicopter design, but in the ’80s, the government provided funding for the X-wing modification of the S-72. At first glance, the X-wing looked like a normal helicopter, albeit one with very thick rotor blades and jet engines strapped to the sides of the fuselage. On takeoff, the rotor would spin just like a normal helicopter, allowing the X-wing to take off vertically. The rotors were unusual in that they did not rely on changing the pitch of the blade to generate lift. Rather, they used a complex compressed air system that bled air from the engines and blew it over the rotor tips, generating extra lift. Once in flight, the rotors would lock in place, acting like normal airplane wings. When the X-wing transitioned to normal flight, it would fly like an airplane since the big rotors would give enough lift for the airframe, and the jet engines would give forward thrust. Unfortunately for Sikorsky, the project quickly ran over budget. The government poured $100 million into the project before it even had the X-wing rotors attached to the airframe. Sikorsky ran three test flights of the airframe without the rotors, but the completed X-wing never got off the ground before the Air Force pulled the plug.

9Percival P.74

During World War II, German engineers drew up various plans for bizarre helicopters and airplanes with the odd propulsion technique of tip-jet rotors. Normal helicopters have rotors that connect to an engine inside the airframe. Tip-jet rotors move the propulsion to the ends of the rotors. Usually, engineers put jet engines or ramjets at the rotor tips to spin the rotors extremely fast. In the 1950s, the British tried to get into the game of experimental helicopters with the unusual Percival P.74. Unlike other tip-jet systems, the P.74 used engines mounted inside the fuselage. Two gas generators sat in the middle of the fuselage. A complex set of tubes moved the gas to the edges of the rotors, where the gas expelled through specially designed ejectors. The system had the advantage of producing much less torque than normal helicopters, meaning that the P.74 only needed a small tail rotor. That is why it looked kind of odd and childish. As unique as the design was, it was not effective at all. Since the gas pipes ran through the middle of the passenger cabin, a flight in the P.74 would not have been pleasant. If it could even get off the ground, that is. Percival diligently tried to get their helicopter airborne, but it stubbornly refused to lift off. The gas ejection system just did not give enough thrust to lift the bulky airframe. Engineers tried their best to redesign the helicopter, but the industry moved on without them, and the P.74 ended up a dead-end.

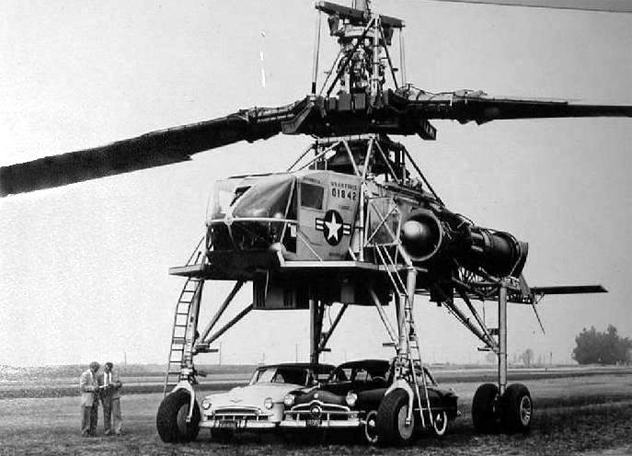

8Kellett-Hughes XH-17

One of the most common uses of helicopters is as flying cranes, lifting heavy and oversize loads to places inaccessible by conventional airplanes. In 1952, the Hughes Aircraft Company designed their first helicopter, the XH-17. At the time, the XH-17 was the largest helicopter in the world, with a gigantic, 36-meter (120 ft) rotor system. The XH-17 used an unusual tip-jet system. Two engines in the fuselage fed bleed air through the rotors and into tip jets. Unlike the P.74, the hot air mixed with fuel and then ignited, meaning that the XH-17 had small jet engines at the end of the rotors. Other than the weird propulsion system, the XH-17 was a Frankenstein’s monster of parts from other airplanes. To cut down on production costs, Hughes used a variety of World War II planes to make the airframe. The cockpit came from a CG-15 glider, the undercarriage came from a B-25 bomber, and the big fuel tank came from a B-29 bomber. When testing commenced, the XH-17 was actually a frightening sight. Flames surged from the jet engines on the rotor tips, and the constant combustion sounded like 1,000 artillery shells going off, according to one newspaper. People up to 13 kilometers (8 mi) away could hear the helicopter when it started up. During testing, the XH-17 revealed that it had an extremely limited range of only about 60 kilometers (37 mi) and had thrust issues. Testing occurred sporadically for three years until Hughes realized that the helicopter would never be an effective system.

7Sikorsky X2

As impressive as helicopters are, their biggest limitation is speed. Helicopters are not very fast, but their flexibility makes up for that limitation. Not content with slow-moving helicopters, Sikorsky embarked on a project to build the fastest helicopter in the world. Back in the 1970s, Sikorsky tried similar experiments with their XH-59A experimental helicopter, but the airframe vibrated so much that Sikorsky dropped the project. With new developments in computer flight control and composite airframe materials, Sikorsky had much more success with the X2. To get the most speed out of the X2, Sikorsky departed from the standard helicopter design. The two rotor blades spin opposite each other in a co-axial configuration, which in itself is not too unique. But instead of adding a tail rotor, Sikorsky placed a pusher propeller blade on the back for pure speed. Since the co-axial configuration negates torque effects, the X2 could completely rely on the pusher propeller for speed. In September 2010, the X2 reached 253 knots in level flight, an unofficial record for top speed of a conventional helicopter. The X2 was never meant for mass production, but it proved to be a highly successful technology demonstrator. With the lessons learned on the X2, Sikorsky is now working on designing a next-generation helicopter for the United States Army. Called the S-79 Raider, the prototype will replace the Army’s aging fleet of observation helicopters using X2 technologies.

6Kamov Ka-22

Russian and Soviet engineers have designed some of the largest and heaviest helicopters that the world has ever seen. In the 1950s, the Soviet Air Force invested in increasing the range of their helicopters to turn them into a workable transportation system. Standard practice was to get the helicopters up to operating altitude by towing them behind a transport, but that technique negated the advantage of being able to vertically take off. To increase the range of helicopters, the Kamov firm designed the Ka-22, a fascinating composite aircraft. Essentially, the Ka-22 was a conventional airplane with rotors attached to the tips of the wings. The two turboshaft engines drove both the puller propellers and the rotor system, requiring that Kamov design a complex and troublesome gearbox arrangement. Despite the constant troubles with the gearbox, the Ka-22 was an impressive vehicle. It could carry 100 passengers and, during test flights, broke eight world records in its weight class. The West got their first look at the Ka-22 during the 1961 Victory Day parade. Nothing in the West was comparable to the Ka-22, and it was a huge shock for Western observers. However, the Ka-22 suffered mechanical problems and had two fatal crashes within a year, wrecking two of the prototype airframes. Instead of giving Kamov the opportunity to fix the problems, the Soviets canceled the project, and composite aircraft experiments became low priority for Soviet airplane firms.

5Fairey Jet Gyrodyne

The Jet Gyrodyne is an interesting combination of tip jets and an autogyro. To use a tip-jet system, Fairey fitted their helicopter with gas burners at the edges of the rotors, propelling the rotor tips to high speed. That system was not incredibly unique among experimental helicopters, but Fairey also wanted their chopper to have the same capabilities as a fixed-wing aircraft. For that to happen, engineers created a system that would allow the rotor to slow down in flight. For take-off, landing, and slow flight, the tip jets provided thrust for the rotor. But once the Jet Gyrodyne reached full speed and altitude, the thrust was slowly turned off in the rotor and transferred to the two pushed propellers. The rotor was not fixed in place and could rotate freely, providing small extra lift. In practice, the Jet Gyrodyne had no problems transferring from helicopter flight to conventional flight. The problem was getting it back into helicopter mode, which required the pilot to engage a complex set of operations with the clutch and the throttle. Unfortunately, that meant that the Jet Gyrodyne was extremely difficult to fly, which was one of the contributing factors to the project’s end in 1961.

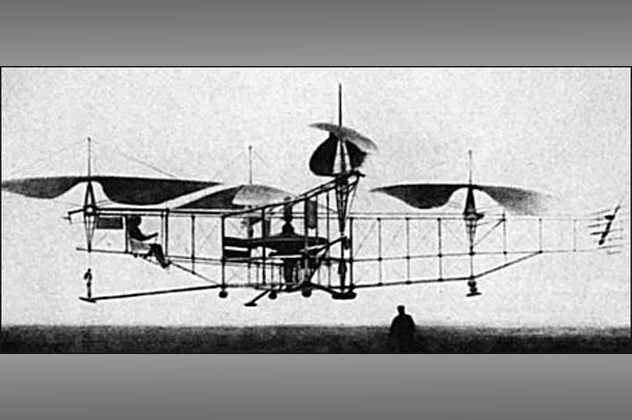

4Oehmichen No.2

Helicopter designs entered the aviation scene fairly early. Engineers grasped the basic principles of helicopter flight and used large parasol wings to offer the necessary lift for their machines. One of the key inventors of early helicopters was French aviation pioneer Etienne Oehmichen. Oehmichen’s first helicopter design failed to get off the ground, so he used a hydrogen balloon to get it to a good test altitude. Oehmichen’s second helicopter (accurately named the No.2) was much more successful. The machine was strange even by the standards of the day. For thrust, the No.2 had four engines driving multiple propellers and rotors. Shaped like a cross, each extremity had a rotor for upward lift. The rest of the airframe was covered in propeller blades spinning in various directions to offer horizontal stability to the craft. A pair of pusher propellers provided forward motion. In testing, the No.2 was relatively successful, capturing the world record for longest endurance flight of a helicopter both in time and distance. As exciting as the early successes were, Oehmichen realized that his machine could only reach modest heights and continually tinkered with the design to get more altitude out of it. His further experiments were only slight improvements, and eventually Oehmichen dropped the project and returned to hydrogen balloons for lift.

3De Lackner HZ-1

As helicopters became a bigger part of military strategy, commanders began looking for new uses of the technology. One of the biggest pushes was to create one-man helicopters that would allow soldiers to fly around the battlefield. To meet the need, a variety of American aviation companies designed outlandish and dangerous helicopters for use by the normal Army soldier. Out of all the designs, none were as dangerous-looking as the de Lackner HZ-1. The HZ-1 had a small engine that drove two contra-rotating propellers. Just above the rotor system was a small platform for one man to stand on. To cut down on weight, de Lackner did not place any sort of safety protection between the pilot and the rotor blades, meaning that any mistake would most likely send the poor soldier straight into the spinning rotor blades. Controls were rudimentary, and the pilots flew mostly by leaning in the direction that they wanted to go, making the HZ-1 basically a helicopter Segway. Testing showed that the HZ-1 had a top speed of 105–110 kilometers per hour (65–70 mph). Surprisingly, testing went relatively smoothly. Some crashes did occur, but none ended in fatalities. The Army was on board for the HZ-1, but changes in tactical doctrine made the HZ-1 unnecessary, and the Army dropped the contract.

2Kamov Ka-56

The Soviet Union also wanted to get into the game of light, personal helicopters. Soviet commanders wanted a light helicopter that could be folded up to fit into a 50-centimeter (20 in) diameter cylindrical container. With this portability, Kamov designed the Ka-56 to drop behind enemy lines or to be used by special forces. Soviet naval commanders also wanted the container to fit inside torpedo tubes so that submarines could send the little helicopter to operatives on beaches or near water. The helicopter was extremely sparse, and almost all the parts could fold up. Experiments with folding the rotor blades showed that they would need to detach from the main airframe, so in the final mock-up, the pilot attached them during assembly. The Ka-56 was extremely easy to put together and only required 10 minutes of assembly time. Unfortunately for Kamov, they could not find a suitable engine for the helicopter, and the project never proceeded beyond ground testing.

1Mil V-12

One of the things that the Soviet Union was best at was creating gigantic airplanes. So it’s not surprising that the Soviet-designed Mil V-12 holds the record for the largest helicopter ever produced, a record that has not been broken since the V-12’s first flight in 1967. Mil began work on the monster helicopter to meet a Soviet air force requirement for a large, heavy-lift helicopter comparable in payload to the fixed-wing An-22 transport. Specifically, the Soviets wanted a helicopter that could carry missiles and other similar loads. The V-12 also would have had use in the civilian sector, specifically in lifting large loads to remote regions of Siberia that did not have airstrips long enough for big transport airplanes. To design the V-12, Mil borrowed the rotor system and power plant from their successful Mi-6 helicopter. The V-12 used two rotor systems, one on each side of the fuselage. The fuselage itself looked like a normal airplane, but used a unique double-decker configuration for the flight deck. A large vertical fin stabilized the helicopter, but the rotors rotated in opposite directions, negating any torque effects. Disaster struck on the first hover test in 1967, when the first V-12 lost power and crashed. Fortunately, the airframe was not totally destroyed, allowing Mil to repair it and continue testing. Despite impressive test results, by the time the V-12 was ready for production, the Soviet air force had made changes to its tactical doctrine that resulted in the V-12 becoming obsolete. Mil did not destroy the prototypes, and both still survive at air museums in Russia. Zachery Brasier is a physics student who writes on the side. Check out his personal blog at zacherybrasier.com.